Comprehensive Guide to Roll Usage Specifications: Key Points from Preparation to Operation

Rolls are vital in metal rolling, and following usage guidelines is key to quality production and safety. This guide covers crucial steps based on industry standards.

Pre - use Preparation

1. Roll Selection & Installation

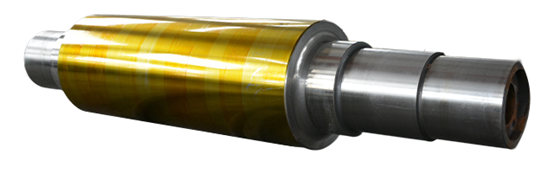

Roll selection varies by process. High - chromium cast iron rolls, favored for their heat and wear resistance, are ideal for hot - rolling, able to withstand up to 1000℃. Alloy forged steel rolls, with strong strength and precision, suit cold - rolling, ensuring tight product tolerances. Cemented carbide rolls are best for profile rolling, especially for complex shapes.

During installation, align the roll axis at a precise 90° to the rolling line, with a 0.05mm/m parallelism tolerance. Laser alignment tools help achieve this accuracy. Tighten bearing housing bolts firmly to prevent vibrations that can harm performance and safety.

2. Mill Parameter Setup

Set rolling speed and reduction according to the roll’s allowable load. Limiting work roll bending stress to 300MPa, as per engineering norms, prevents spalling and breakage. Incorrect settings can cause premature wear and costly downtime.

Operation Tips

1. Temperature & Cooling

In hot - rolling, keep roll surface temperature at 600 - 800℃. Use a high - pressure water system (≥2MPa) for even cooling to avoid thermal cracks. In cold - rolling, maintain 3% - 5% emulsion concentration for lubrication, protecting against scratches and metal adhesion.

2. Load Control

Adjust rolling force gradually to avoid shock loads. Replace rolls when pass wear exceeds 0.5mm in profile rolling to ensure product quality.

3. Real - time Monitoring

Online systems with sensors track roll temperature, vibration (≤50Hz), and rolling force. Detecting anomalies like temperature spikes allows for immediate shutdown, preventing major damage and repairs.

Adhering to these specifications optimizes roll performance, extends lifespan, and boosts metal rolling efficiency.

Stick to these usage specifications, and you’ll keep your rolls in top shape, cut down on costs, and keep your rolling operations running smoothly and efficiently.

Post time: Jun-25-2025