- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

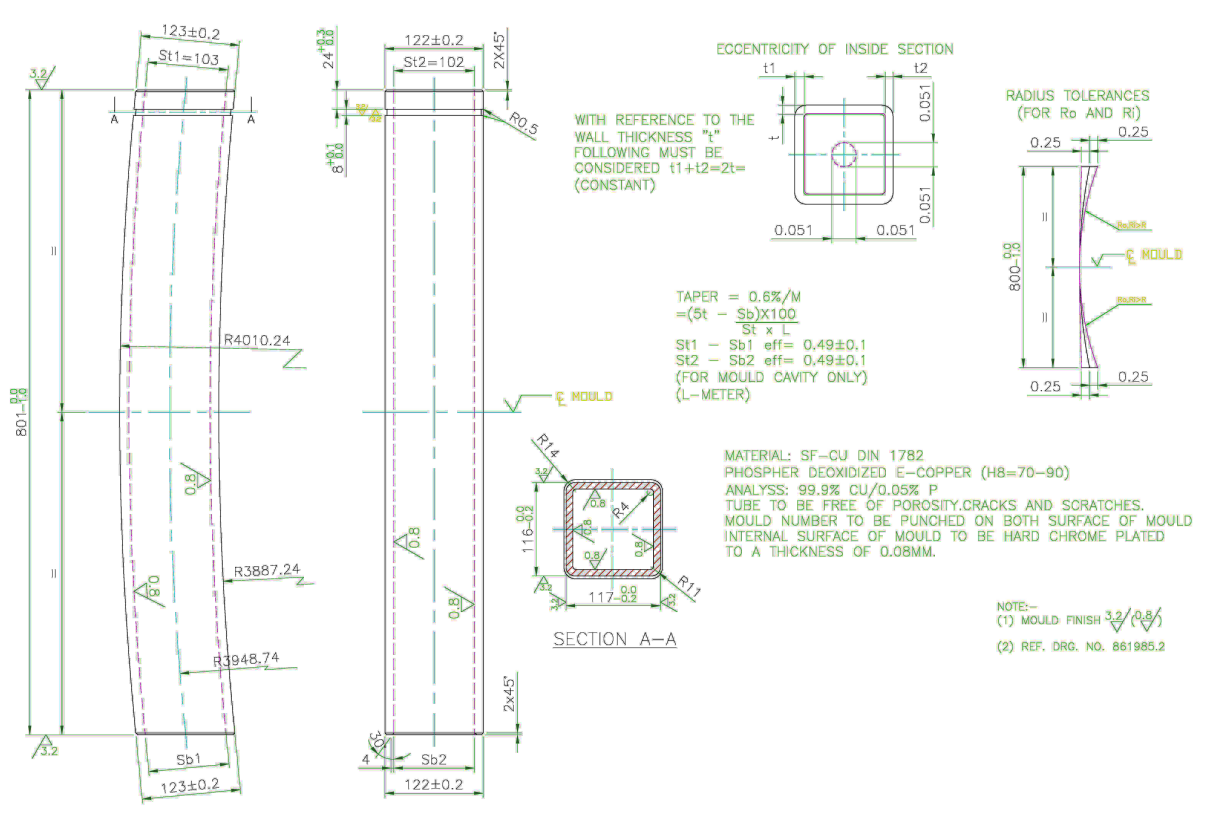

Wholesale Price China Tp2 Copper Mould Tube - Composite Copper Mould Tube – Jinyehong

Wholesale Price China Tp2 Copper Mould Tube - Composite Copper Mould Tube – Jinyehong Detail:

Introduction of Composite Plating

It refers to multi-coating layer. i.e. materials of 2 types shall be coated onto the copper tube in sequence. First layer of a nickel-cobalt alloy is to be coated onto the copper tube as intermediate layer, based on which the second layer of Chrome shall be done as anti-wearPlating Technics:

Composite plating is of Hard Chrome coating, there are two types of so called niclel-cobalt alloy, of which one is amido-sulfonic acid system with nickel aminosulfonate & cobalt aminosulfonate as raw materials whereas the other is sulfuric acid system with nickel sulphate & nickel cobalt as raw materials. The former is superior to the latter in technics for nickel sulphate with high stress likely to drop out from coating. By contrast, amido-sulfonic acid system with lower stress of good stability.

Advantages

Nickel-Cobalt coating as a transitional layer to increase the pass life of liquid metal, in other words, as the expansion factor of copper and chrome is totally different, in the process of heating and cooling, expansion shrinkage will give rise to the drop off from coating. Therefore, before chrome coating, a transitional layer of nickel-cobalt functions a buffer to free from the drop out problems, which drastically decrease the impact onto the coating in the process of heating and cooling increasing the pass life.

Temperature:20℃, (1E-6 /K or 1E-6 /℃)

| Metal | Expansion Factor |

| Copper | 6.20 |

| Nickel | 13.0 |

| Chrome | 17.5 |

Pass Life of liquid Metal : 8,000MT (Chrome Plating)

Pass Life of liquid Metal : 10,000MT(Composite Plating)

copper mould tubes for continuous casting machine have excellent characteristics as follows:

1. Excellent abrasion resistance;

2. Withstand high temperatures;

3. Good corrosion resistance;

4. High strength and high hardness;

5.Good heat dissipation

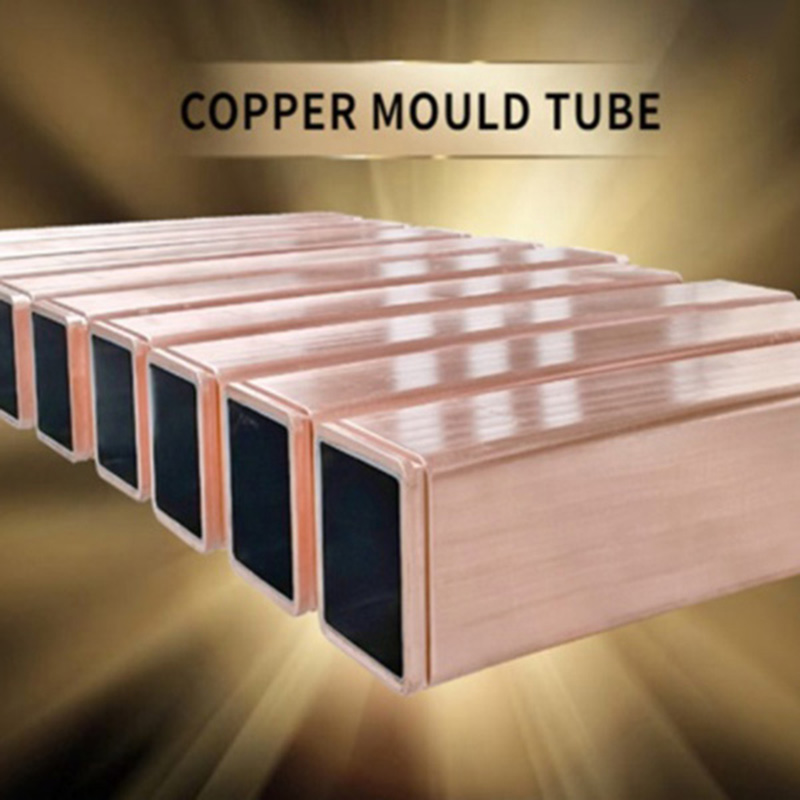

Product detail pictures:

Related Product Guide:

We usually keep on with the principle "Quality To start with, Prestige Supreme". We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for Wholesale Price China Tp2 Copper Mould Tube - Composite Copper Mould Tube – Jinyehong , The product will supply to all over the world, such as: Madagascar, UAE, Salt Lake City, We aspire to meet the demands of our customers globally. Our range of merchandise and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.