- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

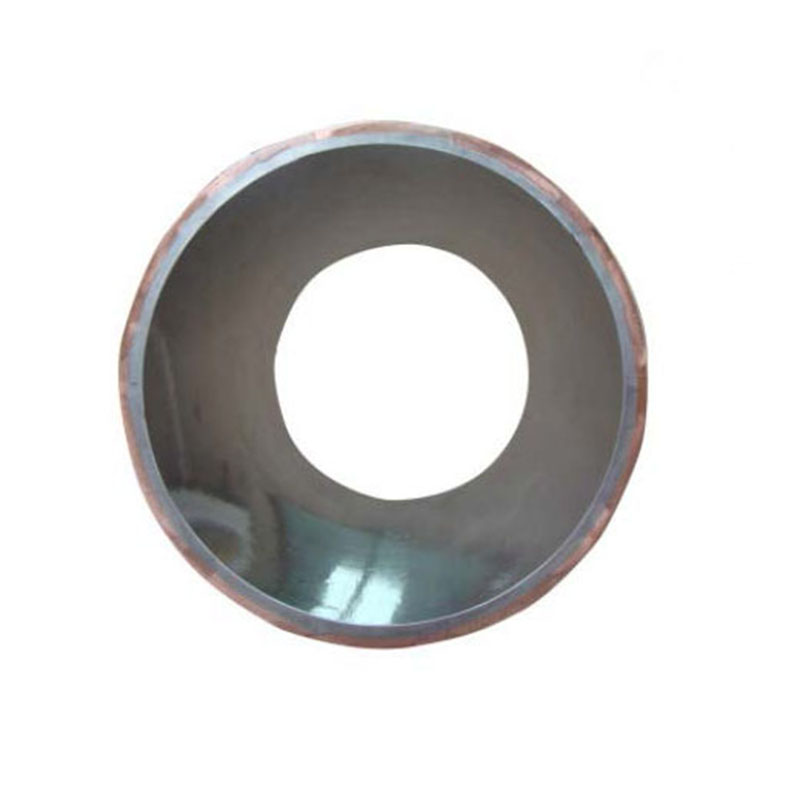

Leading Manufacturer for Carbide Roller - Working rolls for mill rolls – Jinyehong

Leading Manufacturer for Carbide Roller - Working rolls for mill rolls – Jinyehong Detail:

Product Description

|

Product Name |

Hot Strip Mill Work Roll |

|

Process |

Vertical Centrifugal Cast |

|

Material |

High Chrome Steel, High Speed Steel. Alloy Steel , Enhanced High Chrome Iron |

|

Color |

Nickel White |

|

HRC |

41-45 |

|

Brand |

BJMMEC |

|

Usage |

Convention Hot Strip Mills, Thin Slab Compact Strip Mills., |

|

Roll Grade |

MOC |

Application |

|

URMA |

High Chrome Steel |

Roughing stands |

|

STELLA |

Semi High Speed Steel |

Roughing stands |

|

SDSII |

Forged High Alloy Steel |

Roughing stands |

|

SPECRA R |

High Speed Steel |

Roughing stands |

|

CRONA / CRONA TT |

High Chrome Iron |

Finishing stands F1-3(4) |

|

CICRA |

Enhanced High Chrome Iron |

Finishing stands F1-3(4) |

|

SPECRA F/ HSS #3 |

High Speed Steel |

Finishing stands F1-3(4) |

|

ICRA |

Indefinite Chill |

Finishing stands F4-6(7) |

|

MICRA/APEX |

Enhanced Indefinite Chill |

Finishing stands F4-6(7) |

|

VICTURA |

Twin Alloy Steel |

Finishing stands F4-6(7) |

| Manufacture drawing | ✓ |

| Process schedule with ETD date | ✓ |

| QC checking of each process | ✓ |

| Checking report | ✓ |

| Photos &videos of each process | ✓ |

| Photos &videos of each process | ✓ |

| Warranty Time | ✓ |

| The third party Checking | ✓ |

Our Advantage

(1) Over 20 years experiences in manufacturing precision large nonstandard heavy machinery spare parts.

(2) Having five standardized workshops, which are hoisting hook 150 Tons.

(3) Vertical well electric furnace heat treatment – Max. DIA is 6 meter, Max. Depth 9 meters.

(4) Five senior engineers in forging/ heat treatment fields.

(5) OEM & ODM can provided, specialized e-commerce and technical team can provide online service.

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Leading Manufacturer for Carbide Roller - Working rolls for mill rolls – Jinyehong , The product will supply to all over the world, such as: Juventus, Finland, Yemen, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!