- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

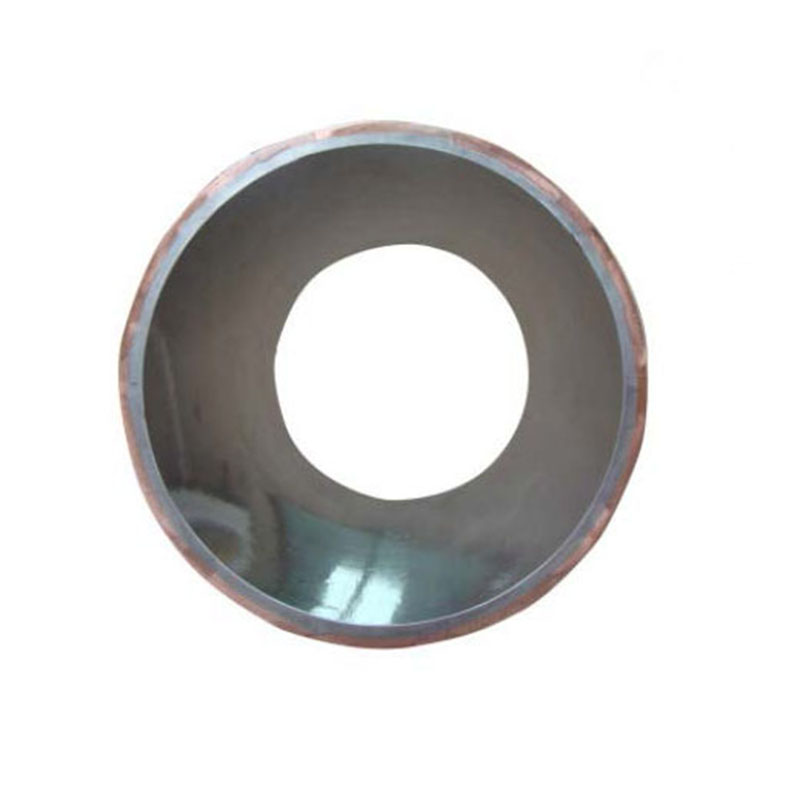

Chinese Professional R6000 Copper Mould Tube - Steel Melting Plant CCM Spare Manufacturer Copper Mould Tubes – Jinyehong

Chinese Professional R6000 Copper Mould Tube - Steel Melting Plant CCM Spare Manufacturer Copper Mould Tubes – Jinyehong Detail:

Product Introduction

✬ Gradually solidifying the molten steel into a shell of the required size and shape;

✬ By the vibration of the mould to remove the shell from the mould wall without being pulled off and break out steel;

✬ By adjusting the parameters of the mould, the casting blank does not have defects such as stripping, bulging and cracking;

✬ Ensure uniform and stable formation of the shell.

Specifications

✬ Material: CuDHP, CuAg, CuCrZr

✬ Coating Layer:Cr,NiCoCr

✬ Round blank from φ100mm to φ1000mm

|

Round billet crystallizer copper tube specification |

||

|

Case section |

Casting machine radius |

Product length |

|

φ90 |

R=3000-5000 |

L=812-850 |

|

φ100 |

R=3000-6000 |

L=812-850 |

|

φ105 |

R=5000-6000 |

L=812-900 |

|

φ110 |

R=6000 |

L=812-900 |

|

φ120 |

R=5250-8000 |

L=812-900 |

|

φ130 |

R=5250-8000 |

L=812-900 |

|

φ140 |

R=5250-8000 |

L=812-900 |

|

φ150 |

R=5250-8000 |

L=812-900 |

|

φ160 |

R=6000-9000 |

L=812-900 |

|

φ180 |

R=6000-10000 |

L=812-900 |

|

φ190 |

R=6000-10000 |

L=812-900 |

|

φ200 |

R=6000-10000 |

L=812-900 |

|

φ210 |

R=6000-10000 |

L=812-900 |

|

φ220 |

R=6000-10000 |

L=812-900 |

|

φ230 |

R=6000-10000 |

L=812-900 |

|

φ280 |

R=6000-10000 |

L=812-900 |

|

φ310 |

R=6000-15000 |

L=812-900 |

|

φ320 |

R=6000-15000 |

L=812-900 |

|

φ330 |

R=6000-15000 |

L=812-900 |

|

φ340 |

R=6000-15000 |

L=812-900 |

|

φ350 |

R=6000-15000 |

L=812-900 |

|

φ400 |

R=6000-15000 |

L=812-900 |

|

φ450 |

R=6000-15000 |

L=812-900 |

|

φ500 |

R=6000-15000 |

L=812-900 |

Focused on design, production and service of metallurgical equipment for 30 years.

All customer-centric Solve your immediate needs in the first time Escorting the production of customers.

If the problem is made by us, we must solve it.And if the problem is not made by us, we will give you collaboration to solve it.

Top technical team, advanced precision machining technology and scientific quality assurance system to provide you with reliable quality products and service.

Product detail pictures:

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of Chinese Professional R6000 Copper Mould Tube - Steel Melting Plant CCM Spare Manufacturer Copper Mould Tubes – Jinyehong , The product will supply to all over the world, such as: Sudan, Rome, Pretoria, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.