- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

China OEM 3 Roll Mill - Good Quality Rolls for Rolling Mill – Jinyehong

China OEM 3 Roll Mill - Good Quality Rolls for Rolling Mill – Jinyehong Detail:

Product Introduce

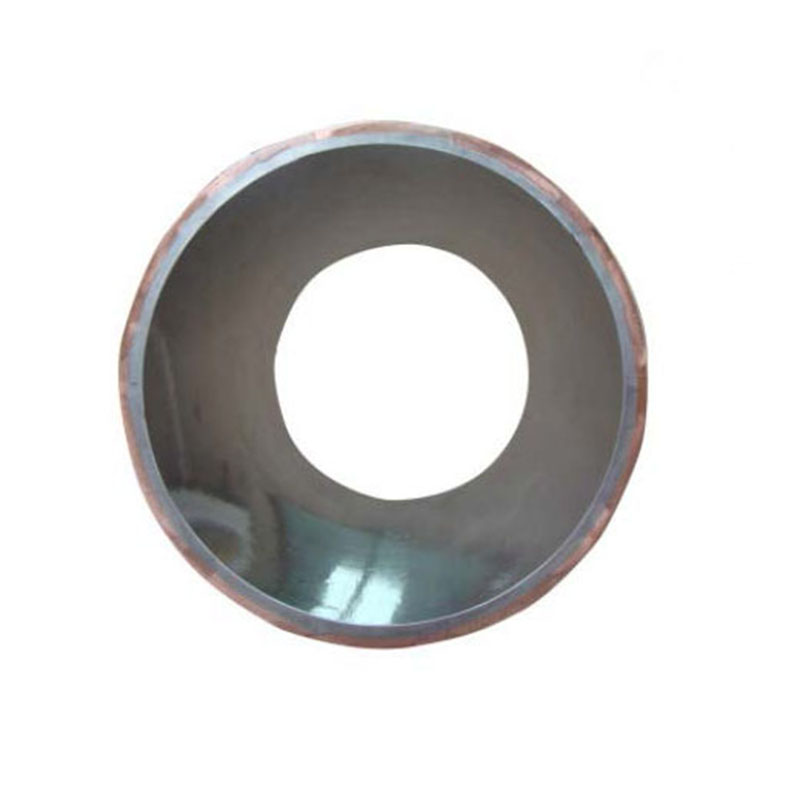

The main working parts and tools on the rolling mill that cause continuous plastic deformation of metal. The roll is mainly composed of three parts: roll body, roll neck and shaft head. The roll body is the middle part of the roll that actually participates in rolling metal. It has a smooth cylindrical or grooved surface. The roll neck is installed in the bearing, and the rolling force is transmitted to the stand through the bearing seat and the pressing device. The shaft head of the transmission end is connected with the gear seat through the connecting shaft, and transmits the rotating torque of the motor to the roller. The rolls can be arranged in the form of two rolls, three rolls, four rolls or multiple rolls in the rolling mill stand.

There are many ways to classify rolls, mainly:

(1) According to product types, there are strip steel rolls, section steel rolls, wire rod rolls, etc.;

(2) According to the position of the rolls in the mill series, they are divided into billet rolls, rough rolls, Finishing rolls, etc.;

(3) According to the functions of the rolls, there are scale-breaking rolls, perforated rolls, smoothing rolls, etc.;

(4) According to the material of the rolls, there are steel rolls, cast iron rolls, cemented carbide rolls, ceramic rolls, etc.;

(5) Press The manufacturing methods are divided into casting rolls, forging rolls, surfacing rolls, sleeved rolls, etc.;

(6) According to the state of the rolled steel, there are hot rolls and cold rolls. Various classifications can be combined accordingly to make the rolls have a clearer meaning, such as centrifugal cast high chromium cast iron work rolls for hot rolled strip steel.

Quick Details for Rolls

Place of Origin: China

Brand Name:BJMMEC

Condition: New

Spare Parts Type:rolls for steel rolling mill

Type:Machining Parts, Roughing Mill / Finish Mill

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Warranty:1 Year

Key Selling Points:Easy to Operate

Applicable Industries:Machinery Repair Shops, Manufacturing Plant

Material:Nodular pearlitic cast iron, Nodular Acicular cast iron

Mill maker:Danieli, Morgen, India,Pakistan,etc

Mill capacity:500000tons/year, 800000tons/year, 1000000ton/year, 2000000tons/year

After-sales Service Provided:Free spare parts, Field maintenance and repair service, Field installation, commissioning and training, Video technical support, Online support

After Warranty Service:

Video technical support, Online support, Spare parts, Field ……

|

Product Description |

|

|

Product description |

The rolls/rollers are of good heat, corrosion, wear-resistant properties, working at high temperature environment on average: 800 to 1200°C, which are used in the steel mills, like CAL (continuous annealing line), CGL (continuous galvanizing line) |

|

Process |

Centrifugal casting for barrel/tube, forging for journal/shaft, static /investment or sand casting for cone/ trunions, welding and machining and grinding |

|

Materials Standards |

ANSI, ASTM, ASME, DIN, GB Materials: High nickel and high chrome heat resistant alloys, cobalt base alloys, like HU, HT, HK, HP, HW, 24/24NbTiZr, 50Cr/50Ni (2.4813), 1.4865, 1.4849, 1.4848, 1.4410, 1.4059, 1.4841, 1.4845, 1.4852, 2.4879 or as per customer’s requirements |

|

inspection |

We have in-house facility for each inspection: composition by spectrometer, size test, mechanical test, NDT/UT/RT/PT/MT/ET |

|

Advantages |

More than 30 years of professional experience and continuous R&D efforts enable us to offer better custom design and engineering advice: Use only new raw material like nickel plate, chrome iron, cobalt, ferrotungsten to guarantee physical property and increased service life of our castings. Experienced workers for foundry, machining and welding guarantee excellent quality and prompt delivery |

|

Package |

packed by seaworthy wooden case or according to buyers’ request. |

|

Delivery |

according to the quantity of the P.O. usually 30 days after the order is confirmed. |

|

Service |

We can make radiant tubes, furnace rollers and other dewaxing or sand casting products according to customers’ DRAWINGS. |

Our Advantage

(1) Professional Team

Build the enterprise quality culture of customer oriented, requirement met and expection surpassed; Implements the quality management concept of Prevention First, and reinforces the quality planning and process control in prophase management; Establishes 6Sigma mechanism for continuous improving, uses DMAIC 5steps, effective methods to optimize organization to reach the goal of high customer satisfaction and low cost.

(2) Excellent Service

Do reply fast, high efficiency.

The customer is supreme!

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for China OEM 3 Roll Mill - Good Quality Rolls for Rolling Mill – Jinyehong , The product will supply to all over the world, such as: Cancun, Kenya, Algeria, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!